www.revacranes.com › rail-allignement-and-tolerancesRail Allignement and Tolerances – Reva EOT Cranes and … Dec 1, 2022 · What is the Tolerance in the Rail Alignments. One of the major parameters in the performance of EOT Cranes is the RAIL Allignment. I perfectly aligned crane rail is a must for the satisfactory performance, life and prevent fatal accidents (like derailing of the crane and falling of the crane) www.overheadcraneconsulting.com › crane-reference-docsEOT Crane Reference Docs – Overhead Crane Consulting, LLC Crane Runway Fabrication and Erection Tolerances. This spec dictates the alignment requirements between the runway (wide-flange) beams and the runway rail. It should be noted that as a result of this standard, the center line of the runway rail’s maximum deviation from the center line of the runway beam is no greater than +/- 3/4 of the width …

www.dgcrane.com › factors-impact-eot-crane-runwayHow Much Factors That Can Impact Your EOT Crane Runway Alignment Nov 15, 2014 · For cranes spanning less than 50 feet, rail-to-rail elevation should be within 3/16-inch, but for larger cranes—spanning 50 to 100 feet—rail-to-rail elevation should be within 1/4-inch, and 3/8-inch for cranes spanning more than 100 feet. cranerepairengineer.com › crane-rail-alignmentCrane Rail Alignment – Structural Design Corporation Operation and Maintenance need to schedule the time to install safety cables and provide access to the crane runway when crane rail alignment is an issue. EOT Crane Survey SDC performs surveys to determine the end truck alignment, wheel alignment, and wheel gauge. Aligning overhead crane rails – HOIST magazine”>www.hoistmagazine.com › features › aligning-overheadAligning overhead crane rails – HOIST magazine Jan 17, 2008 · The trolley will carry hoisting mechanisms and load hooks (1324). Thus, as is usual, the crane operator can move cargo between any two locations between the crane rails. Due to the large scale of typical industrial overhead cranes and heavy loads, proper alignment of crane rails and crane wheels is crucial to safe and efficient operation. rail analysis”>www.konecranes.com › sites › defaultRAILQ™ RUNWAY SURVEY Industry- leading rail analysis rails and affects the usability and lifetime of the crane and its travelling machineries. A runway in poor condition leads to reduced crane performance and reliability, and possibly to safety risks. Konecranes RailQ™ Runway Survey is an industry-leading rail analysis that delivers accurate alignment information of your crane rail and expert

EOT IPSS: 2-02-001-18 CRANES – SAIL”>sail.co.in › sites › defaultDESIGN PARAMETERS FOR EOT IPSS: 2-02-001-18 CRANES – SAIL

handling cranes, maintenance cranes and general purpose cranes etc. 1.1 This standard does not cover single girder cranes. 2. Lifting Capacities – The main, auxiliary & other capacities of different type of EOT cranes shall be as per process/ technical requirement. Nomenclature based on lifting capacity is given in Table-1. 3. overhead crane’s runway rail size …”>www.eotcranekit.com › blog_parts › crane-runway-sizeHow to measure for overhead crane’s runway rail size …

Aug 29, 2021 · A rail alignment and crane alignment survey should be conducted to determine the source of significant runway rail deterioration. As you can undoubtedly see, a proper runway inspection cannot be completed in the time provided for a standard crane inspection and must be treated as a separate item that requires the appropriate amount of time … CODE OF PRACTICE FOR REVAMPING OF EOT CRANES”>sail.co.in › sites › defaultCODE OF PRACTICE FOR REVAMPING OF EOT CRANES

Trolley rail level difference + 4 mm for 2.5 metre trolley gauge. h) Erection of trolley rails and its alignment i) Welding of bridge piece shall be done by low hydrogen MS electrode, after providing back-up strip in the joint. Weld joint in a girder shall be kept staggered. Tested Welders shall be engaged.  EOT CRANES IPSS – SAIL”>sail.co.in › sites › defaultIPSS: 2-02-002-18 ACCEPTANCE NORMS FOR EOT CRANES IPSS – SAIL

6. Transverse displacement of rail from axis of a box type girder at any section, A1 (f/2) + tolerance on LT or + 10 whichever is less E 7. Difference between the distance ‘Ä’ of the longitudinal axis of the crane from the axis of the traveling wheels in case of four wheel cranes or axis of main balancing bogies, where AK is wheel base of the

EOT CRANES IPSS – SAIL”>sail.co.in › sites › defaultIPSS: 2-02-002-18 ACCEPTANCE NORMS FOR EOT CRANES IPSS – SAIL

6. Transverse displacement of rail from axis of a box type girder at any section, A1 (f/2) + tolerance on LT or + 10 whichever is less E 7. Difference between the distance ‘Ä’ of the longitudinal axis of the crane from the axis of the traveling wheels in case of four wheel cranes or axis of main balancing bogies, where AK is wheel base of the

geluids.net › downloads › presentatiesINTERNATIONAL ISO STANDARD 12488-1 – geluids.net The tolerance Δhr given in Tables 4 and 5 for the vertical out-of-plane displacement of a corner of rail wheel of a crane or crane crab, and the corresponding tolerances for tracks given in Tables 2 and 3 are valid for rigid structures travelling or traversing on the rails, i.e. for box beam structures of main girders, crabs or portals. overhead crane’s runway rail size …”>www.eotcranekit.com › blog_parts › crane-runway-sizeHow to measure for overhead crane’s runway rail size … Aug 29, 2021 · A rail alignment and crane alignment survey should be conducted to determine the source of significant runway rail deterioration. As you can undoubtedly see, a proper runway inspection cannot be completed in the time provided for a standard crane inspection and must be treated as a separate item that requires the appropriate amount of time … CODE OF PRACTICE FOR REVAMPING OF EOT CRANES”>sail.co.in › sites › defaultCODE OF PRACTICE FOR REVAMPING OF EOT CRANES Trolley rail level difference + 4 mm for 2.5 metre trolley gauge. h) Erection of trolley rails and its alignment i) Welding of bridge piece shall be done by low hydrogen MS electrode, after providing back-up strip in the joint. Weld joint in a girder shall be kept staggered. Tested Welders shall be engaged. EOT CRANES IPSS – SAIL”>sail.co.in › sites › defaultIPSS: 2-02-002-18 ACCEPTANCE NORMS FOR EOT CRANES IPSS – SAIL 6. Transverse displacement of rail from axis of a box type girder at any section, A1 (f/2) + tolerance on LT or + 10 whichever is less E 7. Difference between the distance ‘Ä’ of the longitudinal axis of the crane from the axis of the traveling wheels in case of four wheel cranes or axis of main balancing bogies, where AK is wheel base of the

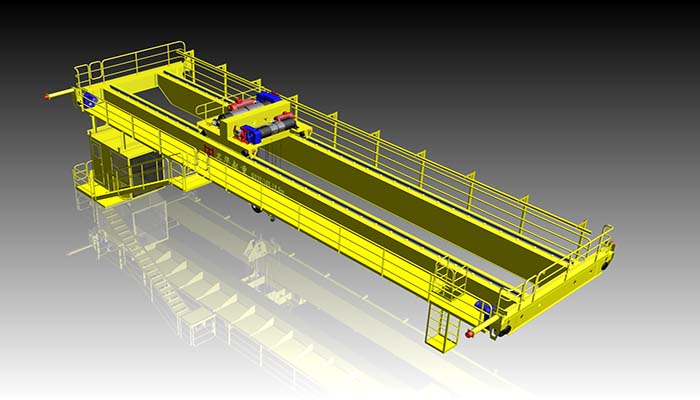

geluids.net › downloads › presentatiesINTERNATIONAL ISO STANDARD 12488-1 – geluids.net The tolerance Δhr given in Tables 4 and 5 for the vertical out-of-plane displacement of a corner of rail wheel of a crane or crane crab, and the corresponding tolerances for tracks given in Tables 2 and 3 are valid for rigid structures travelling or traversing on the rails, i.e. for box beam structures of main girders, crabs or portals. EOT Crane Rail Alignment Services, Pan India”>www.indiamart.com › proddetail › eot-crane-railReporting EOT Crane Rail Alignment Services, Pan India Teamwork CNS Inc. – Offering Reporting EOT Crane Rail Alignment Services, Pan India at Rs 45000/day in Kolkata, West Bengal. Read about company. Get contact details and address | ID: 22174652797 EOT (Electric Overhead Travelling) Crane – Anand Control”>www.anandcontrol.in › blog › modern_eot_cranesEOT (Electric Overhead Travelling) Crane – Anand Control Aug 1, 2020 · EOT (Electric Overhead Traveling) crane is one of the types of overhead cranes, which is also called as bridge cranes. EOT cranes operate on electricity. It needs an operator or pendant station to control the functions of the EOT crane. It consists of a parallel runway connected with a traveling bridge. The hoist is mounted on a traveling bridge. eot crane rail alignment – Cranes For Sale”>www.ykcrane.com › eot-crane-rail-alignmenteot crane rail alignment – Cranes For Sale Jun 8, 2020 · Imbalances in the drive motor output can cause crane skew even if the rail alignment is within tolerances. isaligned or worn rail. Poor runway alignment may result in crane flanging, skewing, or binding. It too can lead to excessive stress to the runway beams and extensive wheel and rail wear. 3. Missing clips.