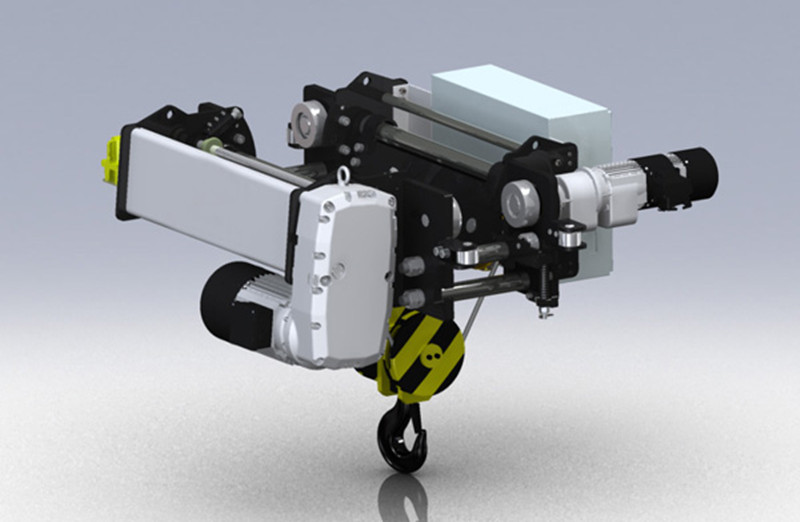

NR Type Wire Rope Electric Hoist

NR wire rope electric hoist is a new generation of wire rope electric hoist with modular, lightweight and intelligent design concepts. There are four structural designs for users to choose from: low headroom running type, standard clearance running type, double beam trolley type, fixed The products are successfully matched with single-girder cranes, double-girder cranes, gantry cranes, cantilever cranes, etc. The series of products meet the different needs of customers.

NR Electric Hoist Features:

1. Without reverse rollers/wheels;

2. Bilateral drive, the reducer directly drives the wheels;

3. The connection of the hoisting mechanism is more convenient and quick, and the trolley structure can also be used;

4. The hoisting mechanism of 3t and 5t hoists is a fully enclosed structure, and other hoists are driven by open gears;

5. Double drive of variable frequency hoisting mechanism with a capacity of 32t~80t;

6. The hoisting mechanism for lifting 3t~16t is C-type structure, and the lifting mechanism for lifting 20t~80t is Z-type structure.

NR Electric Hoist Advantages:

1.Autonomous and Controllable Design Concept of Core Technology

Cooperate with major university research institutes to develop core spare part, and can realizethe independentproduction of core spare part, so as to achieve controllable product quality and controllable construction period.

2. Modular design concept

NR Electric Hoist with modular structure can fully meet your requirements whichowns unprecedented flexibility and can provide you with perfect solutions for personalized needs.

3. Low headroom and compact design concept

All series Electric Hoist are equipped with large diameter drum, which can effectivelyincrease the lifting height and reduce the left and right limits. Crane's dead zone whenworking becomes smaller, which can provide larger using space for the customers.

4. Intelligent and remote operation and maintenance design concept

Intelligent safety monitoring system has the advantage as follows:

a. Calculating the remaining safety cycle of lifting mechanism b. Brake safety operation timesc. Accumulated starts times of hoisting and travellingd. Records the load tonnagee. Overload protection, prohibit users from illegal overloading operationsf. Real-time monitoring of crane's operating Power Supplyg. Motor overheat protectionh. Extensible wireless access point, it can access to user's big data center monitoring

management, so as to realize remote operation and maintenance

5. Design concept of Maintenance-free, energy-saving and Green

Compact structure,Reduce the deadweight,Reduce noise

6. Rugged and safe design concept

a. The whole machine passed the national standard life test (1600 hours)

b. The service life of electrical components is not less than 500,000 times

c. The safe use of brake reaching 1 million times

d. The breaking force of the wire rope reaching grade 2160

e. The hook adopts high-strength T-class hook head

f. 10 years free maintenance of speed reducer